Business Philosophy

In an era of rapid global industrial transformation, we recognize that contract manufacturing has evolved far beyond simple production. Guided by the philosophy of intelligent manufacturing services, we are committed to building a highly efficient manufacturing ecosystem that integrates upstream and downstream processes, fosters proactive communication, and delivers precise execution.

Core Values

·Professionalism ·Communication · Trust

We go beyond getting the job done by carefully aligning and verifying every process to ensure consistent quality and reliable delivery. Through close collaboration with our supply chain, we deliver results our customers can trust.

Mission & Vision

Proudly Made in Taiwan

Our mission is to enhance the global competitiveness of Taiwan’s manufacturing through innovation and intelligent services, positioning HTT as a global benchmark for quality and efficiency on the international stage.

Founding Philosophy

People-Centered, Intelligence-Driven

Our founding team has hands-on manufacturing experience and a deep understanding of customer needs. By combining manufacturing, technology, and communication, we create real value for our customers.

Company Profile

The mold industry is the foundation of industrial manufacturing. With the increasing maturity of metal 3D printing technology, Hong Tai Technology identified future industry trends and was officially established in June 2022.

Hong Tai Technology provides one-stop mold manufacturing solutions, offering full-process control from design to mass production. By integrating the industry’s scarce end-to-end mold manufacturing services, we eliminate the need for multi-party coordination, reduce development time by over 30%, and ensure transparent and controllable costs.

Instead of spending time coordinating multiple vendors, let HTT deliver a complete solution—right the first time.

Industrial Equipment Sales / Metal Additive Manufacturing Services / After-Sales Technical Support & Maintenance / Advanced Mold Design & Engineering / Smart Manufacturing & Machine Management Solutions

Metal

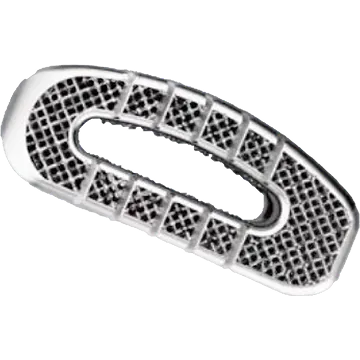

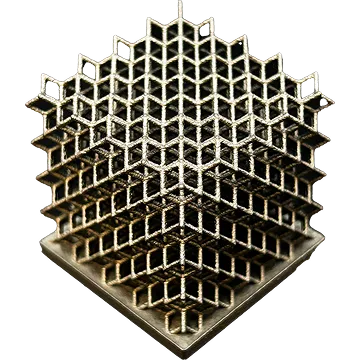

Metal 3D Printing Contract Services / Mold Cooling Channel Design

-

Material Types : 1.2709 (18Ni300 / Maraging Steel / Aging Steel),SUS420 (S136).

Applications : Mold components (inserts) / Conformal cooling / Venting / Combined cooling & venting solutions

-

Material Types : Ti-6Al-4V (Ti64),Commercially Pure Titanium,Aluminum Alloy (AlSi10Mg),Cobalt-Chromium (CoCr),17-4PH Stainless Steel,SUS316L Stainless Steel.

Applications : Metal functional parts / Aerospace components / Semiconductor equipment components, and more

Plastics

Plastic & Ceramic 3D Printing Contract Services

-

Printing Technologies : FDM (Fused Deposition Modeling) / Vat Photopolymerization (SLA/DLP)

-

FDM Materials : PLA / ABS / PC / PC+CF / PETG / TPU, and more

-

Photopolymer Resins : ABS-like Resin / Elastic Resin / Flexible Resin / Ceramic-Filled Resin / Rigid Resin

-

Applications : Structural parts / Strength testing / Appearance / aesthetic validation / Figurines / Assemblies

-

Industries : Product design / Mold development / Prototyping / Footwear industry / Jigs & fixtures

PSR & CSR

We advocate starting with Personal Social Responsibility (PSR)—beginning with individual attitudes, extending to family interactions, and ultimately shaping corporate culture and social responsibility. When every member is willing to contribute to society, a company can unite as a powerful force for positive change.

Centered on the core values of Integrity, Communication, and Well-Being, we approach every decision with sincerity, foster mutual understanding through open communication, and seek fulfillment and joy in both work and life. This is not only our philosophy, but also our commitment to society. We believe that true Corporate Social Responsibility (CSR) begins with individual awareness and action.