Seamless design-to-production workflow shortens development time by over 30%, accelerating time to market.

-

One stop service

A single point of contact integrates design, manufacturing, and supply chain services, eliminating multi-party coordination and significantly improving communication efficiency.

Over 30% faster development

Cost transparency

Clear pricing with flexible options ensures full cost visibility and better budget control.

|

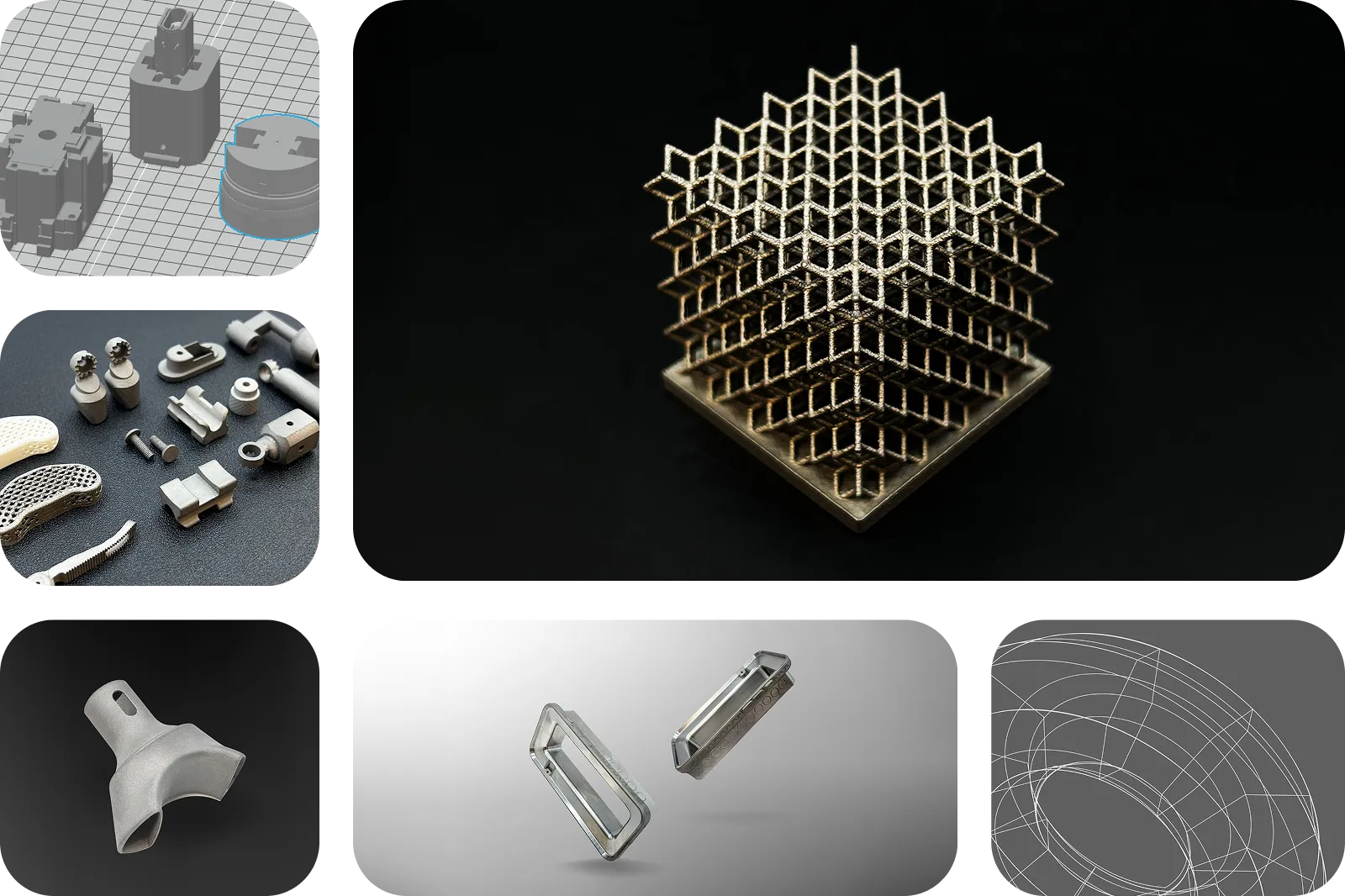

One step|Full control of the mold manufacturing process.

As a professional metal 3D printing provider, HTT integrates a rare end-to-end mold manufacturing service, offering you:

- Mold Design and Optimization

- CNC Post-Processing

- Precision Mold Fabrication

- Conformal Cooling 3D Printing

|

Applicable Scenarios

When facing development pressure, quality demands, and production efficiency challenges, metal 3D printing delivers breakthrough solutions.

- Tight timelines requiring rapid mold trials.

- High-precision or complex mold designs.

- Reducing defects and improving yield in mass production.

-

-

|

Why Choose HTT?

HTT specializes in metal 3D printing and end-to-end mold manufacturing, delivering high-precision, production-ready solutions. By integrating design, simulation, fabrication, and post-processing, we reduce coordination effort, control cost and risk, and shorten development time by over 30%.

From complex designs to rapid iterations, HTT is not just a supplier, but a trusted manufacturing partner.

Exclusive End-to-End Integration Advantage

By integrating in-house expertise and processes, we eliminate common issues in traditional mold development—such as multi-vendor coordination, inconsistent specifications, and cost uncertainty—enabling full control of schedule, quality, and cost through a single point of contact.

Conformal Cooling 3D Printing

Leveraging expertise in metal additive manufacturing, we create customized conformal cooling channels that improve cooling efficiency by 40%, shorten production cycles, and extend mold life.

Experienced Partnership + Exceptional Value

Partnering with a strategic mold expert with 20 years of industry experience and HTT’s process optimization capabilities, we deliver high-value solutions that balance quality and cost.

FAQ

Q

1. What Is Metal 3D Printing?

A

Metal 3D printing, also known as Metal Additive Manufacturing( Metal AM), is a technology that produces metal parts using 3D printing principles. Unlike traditional subtractive manufacturing methods such as CNC machining, it builds components layer by layer, forming complete three-dimensional structures.

Q

2. What are the common metal 3D printing technologies?

A

- SLM(Selective Laser Melting) / DMLS(Direct Metal Laser Sintering):Uses a high-power laser to selectively melt metal powder, delivering high precision and high part density, suitable for engineering applications.

- EBM(Electron Beam Melting):Uses an electron beam to melt metal powder in a vacuum environment; suitable for high-temperature materials such as titanium alloys, offering high build speed but a relatively rough surface finish.

- DED(Directed Energy Deposition):Uses a laser or electron beam to simultaneously melt metal powder or wire, enabling part repair and large-scale printing.

- Binder Jetting(Metal Binder Jetting):Uses a binder to bond metal powder, followed by sintering; offers low cost and high speed but requires additional post-processing.

Q

3. What are the application areas of metal 3D printing?

A

The flexibility of metal 3D printing enables outstanding performance across a wide range of industries:

- Aerospace:Manufacturing lightweight, high-strength structural components such as turbine blades and brackets to reduce aircraft weight.

- Automotive:Producing performance parts, engine components, exhaust systems, and even racing parts.

- Mold Manufacturing:Rapid fabrication of molds with complex cooling channels to improve cooling efficiency and extend product life.

- Jewelry and Art Design:Creating intricate forms that are difficult or impossible to achieve with traditional casting methods.

Leave It to HTT — One Partner, Total Solution

Instead of spending time coordinating multiple vendors, trust HTT to handle everything from start to finish.

Mold design and optimization are critical to ensuring molding quality, improving production efficiency, and reducing manufacturing costs. Through integrated analysis of structural design, runner layout, cooling systems, and molding simulation, potential issues are identified early and designs are precisely optimized—extending mold life, enhancing stability, and accelerating product development.

Contact us to unlock new possibilities in mold manufacturing!

Get in touch with us and let’s build an innovative manufacturing future together.