1

1

1

1

Why Choose the M400?

High-Productivity Configuration

By integrating in-house technologies and workflows, we eliminate common challenges in traditional mold development—such as multi-vendor coordination, inconsistent specifications, and cost uncertainty—enabling centralized control of schedule, quality, and cost through a single point of contact.

Equipped with four high-precision 500W/1000W fiber lasers, intelligent variable-speed control, and bidirectional powder recoating completed in 3 seconds, combined with a large 350 × 400 × 400 mm build volume, the M400 delivers an efficient solution for large-scale production.

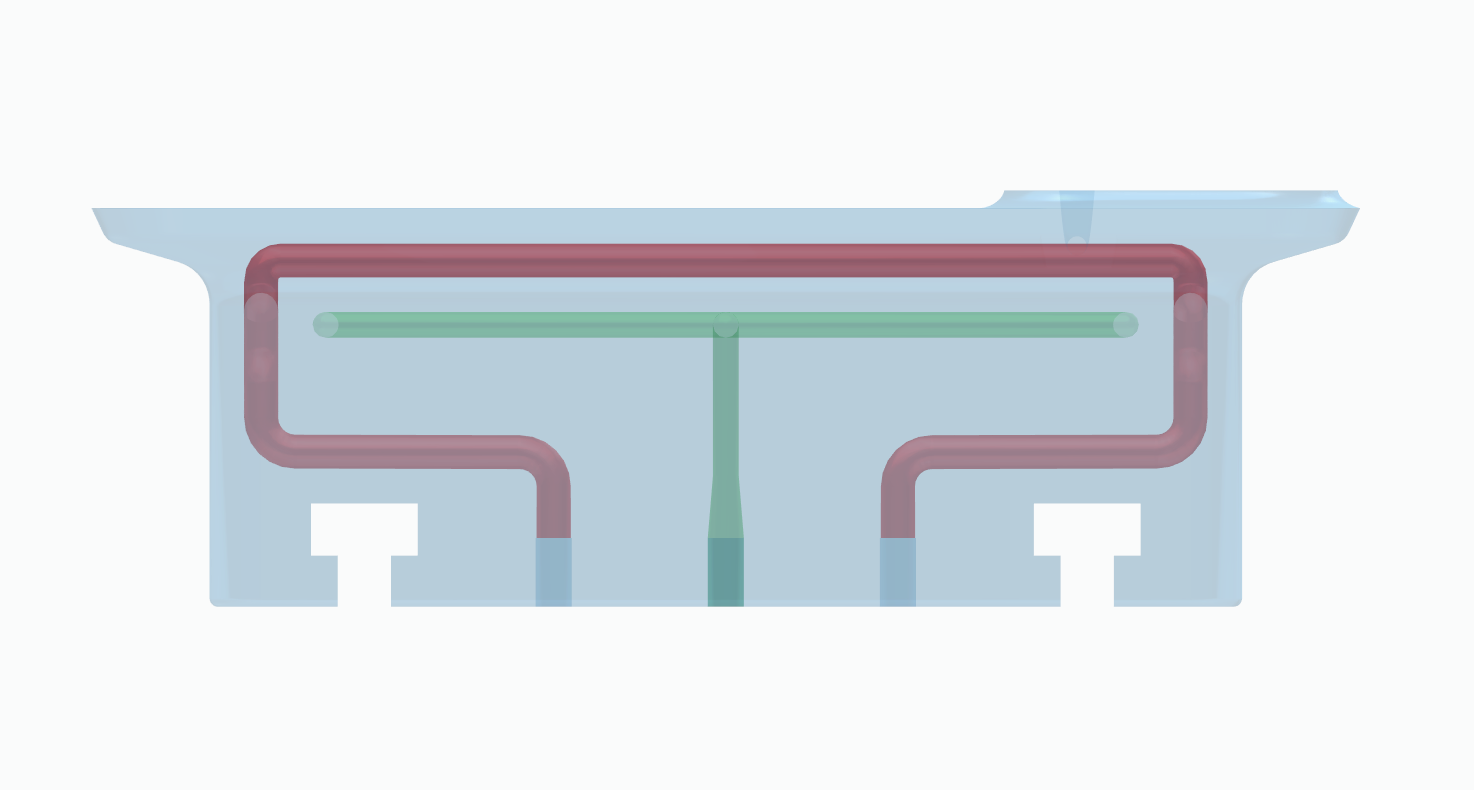

Conformal Cooling 3D Printing Technology

The filtration system adopts next-generation PTFE-coated filter elements compliant with H13 standards, achieving 99.9% capture efficiency for particles as small as 0.3 μm.

The sieving system features self-cleaning functionality with a filter lifespan exceeding 5 years. Optimized airflow design enables safe and efficient waste recovery in an inert gas environment, ensuring optimal printing conditions.

Experienced Partnership + Exceptional Value

With seamless multi-laser stitching, the M400’s automatic laser calibration system customizes scanning strategies based on process conditions, achieving calibration accuracy of ±0.05 mm—ensuring superior process stability and part quality.

1

1

1

1

Why Choose the M400s?

High-Efficiency Mold Integration

Integrates multiple components into a single structure, effectively reducing assembly errors and simplifying production processes.

Shortened Development Cycle

Eliminates traditional mold development steps, enabling rapid mold trials and ideal solutions for low-volume production.

Conformal Cooling Support

Built-in complex cooling channel designs significantly improve product stability and mold lifespan.

High Material Compatibility

Supports commonly used shoe mold powders such as 316L stainless steel, AlSi10Mg, and 17-4PH (SUS630).

Ventilation Design Support

Enables effective gas venting and foaming control during molding.

Ultra-High Surface Precision

Ensures precise reproduction of outsole details, logos, and textures.

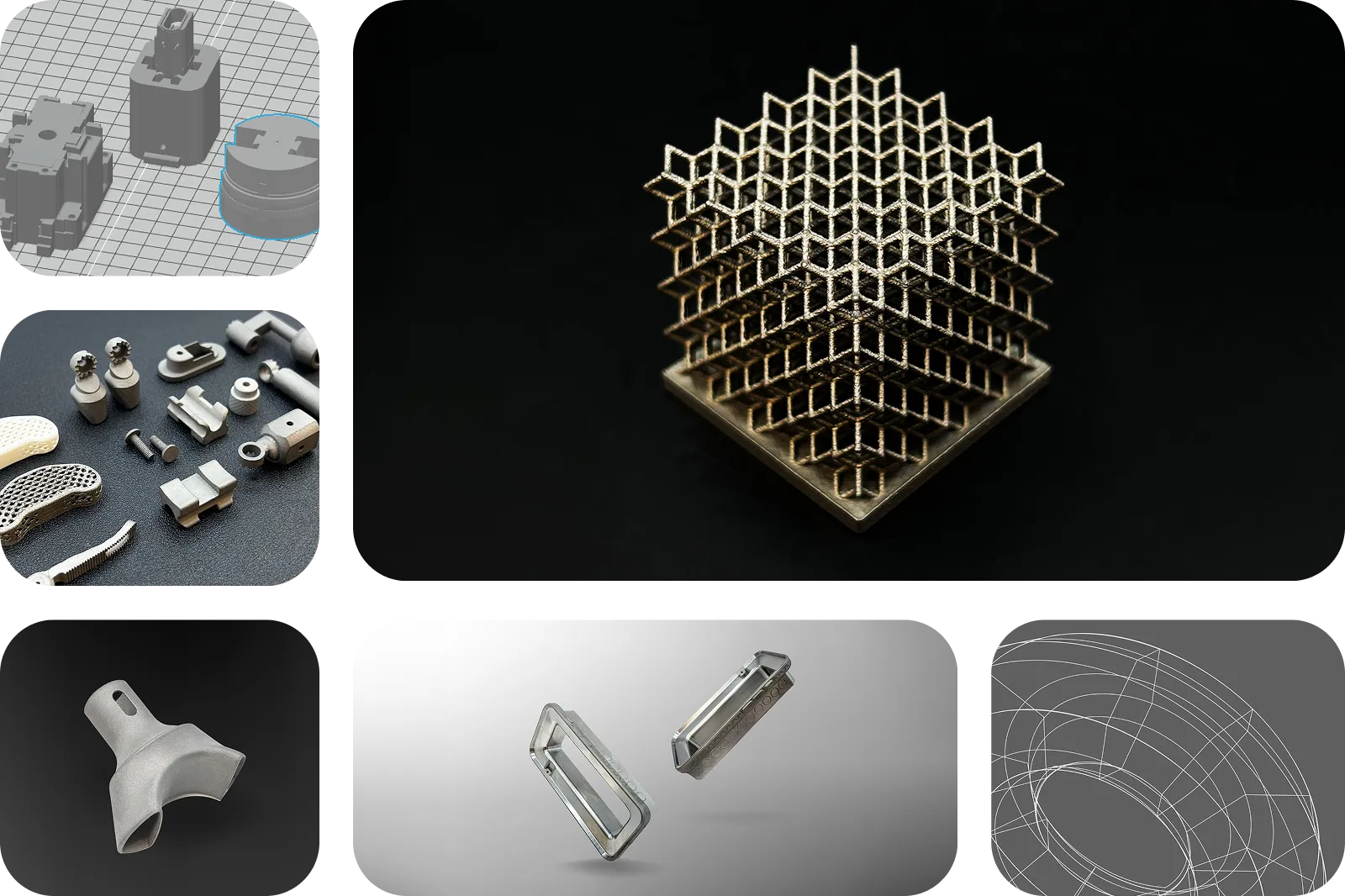

Metal 3D Printing Systems

Technology Used : Selective Laser Melting (SLM)

Available Models : M400、M400s

⬇ Contract Manufacturing Services ⬇

Printable Materials : 8Ni300、1.2709、M789(CX)、H13、HTC45(High Thermal Conductivity)、LTX420、SUS420J2、Aluminum Alloys(AlSi10Mg、6061)、17-4PH、 316L、Ti64、Pure Tungsten、4130、Inconel718

Applicable Industries : Mold components (inserts) for cooling / venting / cooling + venting,metal parts, aerospace components, and semiconductor equipment parts.

Contact us to unlock new possibilities in mold manufacturing!

Get in touch with us and let’s build an innovative manufacturing future together.